Mixing Equipment & Engineering Services

AGImix by Mixing Equipment & Engineering Services is a trusted Indian brand specializing in the design, manufacturing, and servicing of high-performance industrial agitators, mixers, and reactors for chemical, pharmaceutical, food, and water treatment industries.

Industries We Serve

Providing efficient mixing solutions across a wide range of industries

Chemical

Pharma

Food

Paint

Water Treatment

Cosmetics

Chemical

Pharma

Food

Paint

Water Treatment

Cosmetics

Our Products

View More

Why Choose AGImix Industrial Agitators?

At AGImix – Mixing Equipment & Engineering Services, we understand that every mixing application has unique requirements. That’s why our agitators are designed with flexibility and customization in mind, allowing them to perform seamlessly across diverse industrial processes — from blending chemicals to mixing high-viscosity substances.

Here’s why industries trust AGImix agitators:

⚙️ Tailored Solutions for Every Process

AGImix offers a wide range of agitator configurations to meet specific mixing needs, including top-entry, side-entry, and bottom-entry designs. Each unit is engineered to ensure optimal performance for your application.

🧱 Robust and Reliable Construction

Manufactured using premium materials such as stainless steel, mild steel, and Hastelloy, our agitators are designed to withstand harsh operating conditions and deliver long-term durability.

💡 Energy Efficiency and Cost Savings

With advanced impeller designs and precision engineering, AGImix agitators minimize energy consumption while achieving superior mixing performance — helping industries reduce operational costs and improve productivity.

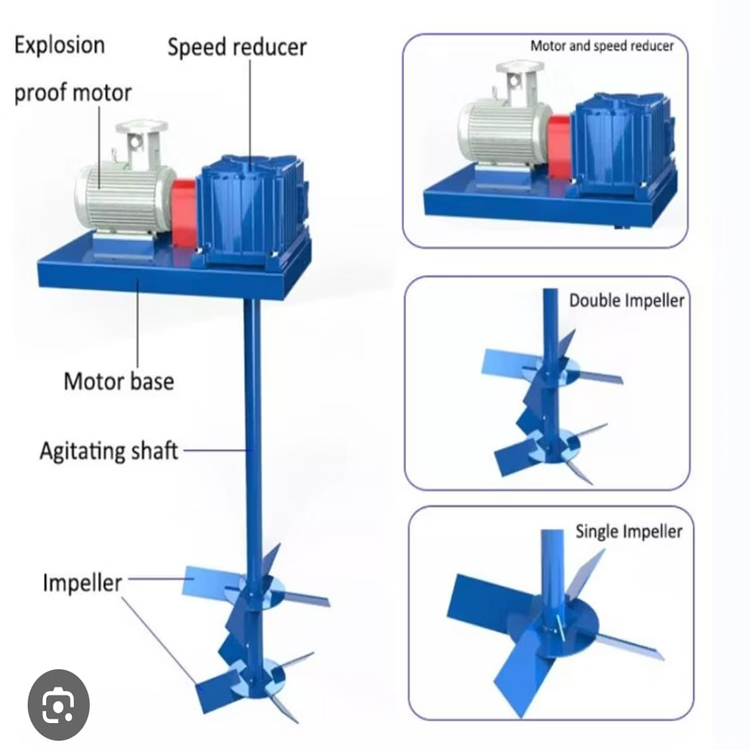

Types of Industrial Agitator Offered by AGImix

🔹 Top-Entry Agitators

Ideal for large tanks and high-volume applications, AGImix’s top-entry agitators deliver powerful and efficient mixing performance. With variable speed controls and advanced impeller designs, these agitators are perfect for blending liquids, suspending solids, and achieving homogeneous mixtures across various industries.

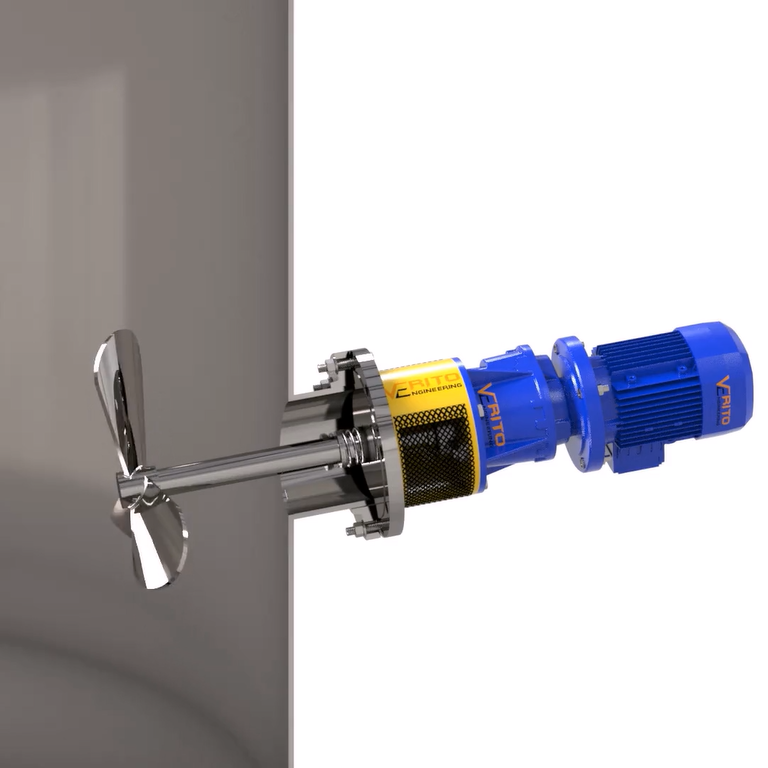

🔹 Side-Entry Agitators

Designed for applications with limited headroom, such as storage tanks and process reactors, AGImix’s side-entry agitators ensure excellent fluid circulation and mixing uniformity. They are widely used for maintaining product consistency, blending, and preventing sedimentation in large-capacity tanks.

Key Features of AGImix Industrial Agitator

Precision Mixing Control

Equipped with advanced speed control systems and customized impeller configurations, AGImix agitators ensure precise and consistent mixing performance for every batch, regardless of viscosity or volume.

Wide Material Compatibility

AGImix agitators are available in multiple construction materials, including SS304, SS316L, Hastelloy, and Titanium, providing superior resistance to corrosion, abrasion, and high-temperature fluids.

Advanced Impeller Designs

AGImix offers a diverse range of impeller types — axial flow, radial flow, and turbine designs — each optimized to enhance mixing efficiency, product uniformity, and process reliability.

Flexible Mounting Options

With adaptable configurations such as top-entry, side-entry, and bottom-entry mounts, AGImix agitators can be seamlessly integrated into new or existing tanks and reactors, ensuring easy installation and operation.

Technical Specifications – AGImix Industrial Agitators

Power Ratings:

Available from 0.25 HP to 100 HP, catering to diverse mixing requirements — from gentle blending to heavy-duty industrial mixing operations.

Impeller Speed:

Variable speed options ranging from 0.1 RPM to 1,500 RPM, offering precise control over mixing intensity and process efficiency.

Tank Capacity:

Engineered to suit vessels of all sizes — from small laboratory tanks to large-scale industrial reactors exceeding 100,000 liters.

Material Options:

Constructed from Stainless Steel (SS304/SS316L), Hastelloy, Titanium, and other corrosion-resistant materials, ensuring long service life and superior chemical compatibility.

Seal Types:

Offered with a variety of sealing options, including mechanical seals, lip seals, and custom-engineered seals, designed to meet the demands of specific applications and operating conditions.

Advantages of AGImix Agitators

1. Enhanced Mixing Efficiency

AGImix agitators are engineered to deliver fast, uniform, and consistent mixing results — reducing process cycle times while maintaining superior product quality.

2. Versatility Across Applications

AGImix agitators perform efficiently across a wide range of industrial processes, including blending, homogenization, dissolution, suspension, and heat transfer applications.

3. Reduced Maintenance and Downtime

Built with premium materials and precision-engineered components, AGImix agitators ensure long-term performance with minimal maintenance requirements and downtime.

4. Energy Savings

With advanced impeller designs optimized for maximum power efficiency, AGImix agitators offer significant energy savings without compromising on mixing performance.

5. Customizable for Specific Needs

AGImix provides tailor-made agitator solutions — including impeller design, shaft dimensions, and mounting configurations — to meet your exact process and industry requirements.

Applications of AGImix Industrial Agitators

AGImix industrial agitators are trusted across multiple industries for their efficiency, durability, and precision engineering. Designed to deliver consistent performance, they serve a wide range of mixing applications, including:

🔹 Chemical Processing

Efficient mixing of reactants, catalysts, and additives to ensure consistent product quality and optimal chemical reactions.

🔹 Water and Wastewater Treatment

Used for homogenization, flocculation, and aeration processes, AGImix agitators enhance treatment efficiency and water quality.

🔹 Pharmaceuticals

Ensure precise blending of sensitive ingredients in drug formulations while maintaining hygiene and compliance with GMP standards.

🔹 Food and Beverage

Ideal for blending ingredients, maintaining texture uniformity, and ensuring sanitary conditions in food and beverage production.

🔹 Mining and Minerals

Enable the suspension of solids, blending of slurries, and mixing in mineral extraction and ore processing applications.

⚙️ Engineering Excellence by AGImix – Mixing Equipment & Engineering Services

AGImix represents the pinnacle of mixing technology, providing industries with reliable, efficient, and fully customizable agitator solutions.

With a strong focus on precision design, quality manufacturing, and customer satisfaction, AGImix agitators empower businesses to achieve superior mixing performance across diverse industrial sectors.

Experience the reliability, innovation, and excellence of AGImix agitators — engineered to take your mixing processes to the next level.

Our Clients Say

Hear what our valued clients have to say about AGImix - Mixing Equipment & Engineering Services

⭐️⭐️⭐️⭐️⭐️

"Reliable Performance and Excellent Build Quality!"

We have been using AGImix agitators for our chemical mixing processes, and the results have been outstanding. The equipment runs smoothly and requires minimal maintenance.

— R. Sharma, ChemPro Industries

⭐️⭐️⭐️⭐️⭐️

"Truly Professional Service from Start to Finish"

From design consultation to installation, the AGImix team provided complete technical support. Their commitment to quality and precision is impressive.

— Priya Mehta, AquaTreat Solutions

⭐️⭐️⭐️⭐️⭐️

"High Efficiency and Energy-Saving Design"

We replaced our old mixers with AGImix agitators and noticed immediate energy savings and better homogeneity in our batches.

— Arindam Roy, PharmaBlend Pvt. Ltd.

⭐️⭐️⭐️⭐️⭐️

"Customized Solutions That Perfectly Fit Our Needs"

AGImix designed a custom top-entry agitator for our food processing plant. The performance, durability, and after-sales support are excellent.

— S. Banerjee, FreshMix Foods

⭐️⭐️⭐️⭐️⭐️

"Dependable Partner for Long-Term Industrial Operations"

We’ve been working with AGImix for over three years, and their products continue to perform flawlessly. Their engineering team understands our industry needs deeply.

— Amit Desai, Hydrotech Engineering

Our Infrastructure

At AGImix - Mixing Equipment & Engineering Services, we take pride in our advanced infrastructure that powers innovation, precision, and reliability.

🔧 Manufacturing Facility

Our production unit is equipped with modern fabrication tools, CNC machines, balancing equipment, and precision measuring instruments — ensuring exact manufacturing standards for every AGImix product.

⚙️ Design & Engineering Department

Our R&D engineers use advanced 3D CAD software and simulation tools to design efficient, durable, and customizable agitators, optimized for performance and energy efficiency.

🧪 Quality Control

Every AGImix product undergoes strict inspection and testing at all stages — from raw material selection to final performance check — ensuring flawless quality and durability.

🚛 Storage & Logistics

We maintain a well-organized storage and logistics system that enables us to handle bulk orders efficiently and ensure timely delivery across India and abroad.

👷 Skilled Workforce

Our team of experienced engineers, technicians, and quality inspectors work with dedication to ensure each AGImix product reflects our commitment to engineering excellence.

AGImix continues to invest in technology, innovation, and skilled talent — strengthening our manufacturing foundation to deliver the best in industrial mixing and agitation solutions.

Get in Touch

We’re here to assist you with your industrial mixing and engineering needs. Reach out to our team for inquiries, quotations, or technical support.

📍 Office Address

Jamaibati, Brahmanpara, Haripal, Hooghly,

West Bengal - 712405

📞 Contact Details

Phone: +91 81599 58197

Email: sales.mixingequipment@gmail.com